- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

PPR Pipes And Fittings Manufacturers

What’s PPR pipes and fittings?

PPR, also called PPRC, full name as Polypropylene Random Copolymer.

PPR pipes and fittings are made by Polypropylene Random Copolymer material, produced through a continuous extrusion process (for PPR pipe) & injection moulding process (for PPR fittings).

What’s the main application of PPR pipes and fittings? What’s the main benefits of PPR pipes and fittings?

PPR pipes and fittings have been widely used as cold & hot water systems of houses, hotels and other commercial buildings. In addition, they are also used for the industrial piping for transferring water, sanitary liquids, liquid food products, compressed air, and aggressive chemicals eg. highly acidic or alkaline solutions. Building central radiator heating water, usually in a circular loop piping arrangement.

Main benefits of PPR pipes and fittings:

※ Green pipe

PPR pipe is a kind of green pipe. Non-Toxic, hygienic for drinkable water supply.

※ Excellent temperature resistance & high working pressure

PPR pipes can be worked at the max.95℃ water temperature & the max. PN25 bars working pressure.

※ Reliable jointing

Heat-fusion is the jointing method for PPR pipe. The PPR pipes & fittings have the same molecular structure, the heat-fusion technology makes the PPR molecular structure recombined as a integration. Heat-fusion jointing makes the PPR pipes the most reliable connection with 100% leak free.

※ Low thermal conductivity

The low thermal conductivity of PPR pipes makes them usable in the cold/hot water supply systems in the commercial sectors.

※ Recycled for use to save resource

PPR pipes and fittings can be recycled used, so it will save the resource.

※ Long service time

PPR pipe is designed for a long lifespan up to 50 years under normal conditions.

Which specifications of PPR pipes and fittings can SUNPLAST provide? Which standards do SUNPLAST PPR pipes and fittings be made into?

SUNPLAST PPR pipes and fittings are made into GB/T 18742 standard and EN ISO 15874 standard in English version. At the same time, it can fully conforms to DIN8077/8078 standard.

※ PPR pipe

SUNPLAST PPR pipes can be provide from dn20-110mm, with pressure ratings PN10 bars/PN12.5 bars/PN16 bars/PN20 bars.

|

PPR Pipe Standard: GB/T 18742 , DIN 8077/8078, EN ISO 15874 |

|||

|

S5/ PN10bars |

S4/ PN12.5bars |

S3.2/ PN16bars |

S2.5/ PN20bars |

|

20×2.0 |

20×2.3 |

20×2.8 |

20×3.4 |

|

25×2.3 |

25×2.8 |

25×3.5 |

25×4.2 |

|

32×2.9 |

32×3.6 |

32×4.4 |

32×5.4 |

|

40×3.7 |

40×4.5 |

40×5.5 |

40×6.7 |

|

50×4.6 |

50×5.6 |

50×6.9 |

50×8.3 |

|

63×5.8 |

63×7.1 |

63×8.6 |

63×10.5 |

|

75×6.8 |

75×8.4 |

75×10.3 |

75×12.5 |

|

90×8.2 |

90×10.1 |

90×12.3 |

90×15.0 |

|

110×10.0 |

110×12.3 |

110×15.1 |

110×18.3 |

Click to view PPR PIPES AND FITTINGS to download our price list

PPR pipe fittings are available from dn20-110mm, with regular configurations: coupler, reducing coupler, female or male thread coupler, elbow, reducing elbow, female or male thread elbow, wall-plated female elbow, tee, reducing tee, female or male thread tee, end cap, ball valve, stop valve.,etc.

All PPR pipe fittings are PN25 bars, suitable to weld all PPR pipes in different pressure ratings.

What colors of PPR pipes and fittings that SUNPLAST can provide?

SUNPLAST PPR pipes and fittings are regularly provided in white, green or grey colors. The other colors are also available as per customers’ request.

What’s the technical characteristics of SUNPLAST PPR pipe and fittings?

The PPR pipes and fittings are made into GB/T 18742 standard and EN ISO 15874 standard, and can fully meet with all requirements in the standards:

|

Characteristic |

Requirements |

Test Methods |

|

|

Physical characteristics for PPR pipe |

|||

|

Impact resistance of PPR pipe (0℃) |

<10% |

ISO 9854 |

|

|

Longitudinal reversion of PPR pipe (135℃) |

≤2% |

EN 743 |

|

|

Thermal stability by hydrostatic pressure testing of PPR pipe (110℃, 1.9Mpa) |

No bursting during the test period |

EN921

|

|

|

Melt Flow Rate of PPR pipe (2.16Kg,230℃,10min.) |

30 % maximum difference compared with compound |

ISO 1133 |

|

|

Mechanical characteristics for PPR pipe |

|||

|

Resistance to internal pressure |

Hydrostatic (hoop) stress 16.0Mpa; Temperature 20℃; Test time 1 hour No failure during the test period |

EN 921

|

|

|

Hydrostatic (hoop) stress 5.1Mpa; Temperature 95℃; Test time 22 hour No failure during the test period |

|||

|

Hydrostatic (hoop) stress 4.2Mpa; Temperature 95℃; Test time 165 hour No failure during the test period |

|||

|

Hydrostatic (hoop) stress 3.5Mpa; Temperature 95℃; Test time 1000 hour No failure during the test period |

|||

How does SUNPLAST guarantee the quality of PPR pipe and fittings? What’s the warranty term in quality?

The quality of incoming material determines the qualification of the piping. To guarantee the best quality, SUNPLAST adopts 100% virgin PPR material R200P from South Korea Hyosung, which is recognized as one of the best quality material in the world.

We have been implementing ISO9001 management during the whole production. All PPR pipe and fittings shall adopt a strict testing during the whole production process, from which all manufacturing defect or inferior-quality product can be found.

All PPR pipes and fittings are covered by a 5-year warranty period. This guarantee is subject to a proper product application and adherence to this installation manual.

What’s the packing methods of SUNPLAST PPR pipes & fittings?

SUNPLAST PPR pipes are packed in bars with 4m or 5.8m length. A bundle of pipes (such as 120m length for dn20mm pipe) be packed by a PP bags with plastic bags wrapped inside.

PPR fittings be packed in cartons with plastic bags inside.

What’s the difference between PPR pipes & HDPE pipe?

There are three main difference between PPR pipes & HDPE pipe:

1) . PPR pipes are made of polypropylene material while HDPE pipe is polyethylene material, like PE100 or PE80 material.

2) . PPR pipes are suitable for cold & hot water portable piping systems, but HDPE pipe can be used as cold water pipe only.

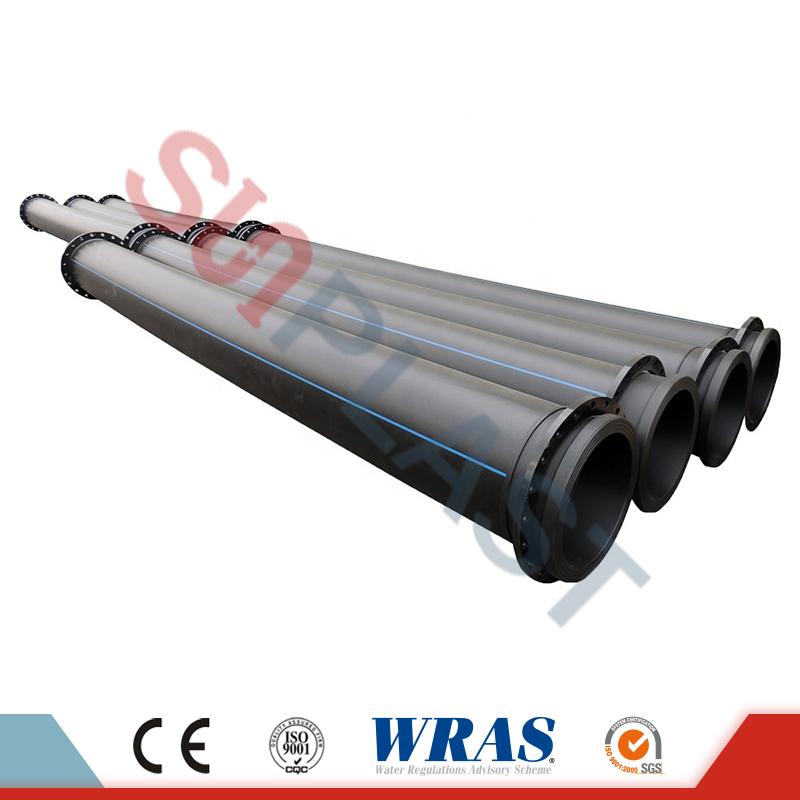

3) . PPR pipe normally available in small diameter like dn20-110mm, but HDPE pipe can be supplied from dn20-1200mm (SUNPLAST can provide).

How to choose between PPR pipes & PEX-AL-PEX pipe for hot water plumbing? Which one is better?

Both PPR pipes & PEX-AL-PEX pipe can be serviced at max. 95℃ temperature, but they are two different pipe that are made of different materials: PPR pipes are made of single polypropylene material, while PEX-AL-PEX pipes are composite materials with a five layers’ structure of PEX, Aluminum & Adhesive.

Benefits of PPR pipes for hot water plumbing:

※ PPR pipes are connected by a heat-fusion technology, the PPR pipes & fittings are bonded together as a integration, so they are 100% leak-free permanent when pressure test is made. PEX-AL-PEX pipe can be installed by mechanical brass fittings, and a risk of leak when service for long time.

※ PPR pipes can offer higher pressure ratings for choice, which are PN10/PN12.5/PN16/PN20, while PEX-AL-PEX pipe is PN10 only.

Benefits of PEX-AL-PEX pipes for hot water plumbing:

※ PEX-AL-PEX pipe is flexible, and can be provided in 100m-500m coils, but PPR pipes can be supplied in bars of 4m or 5.8m length only.

※ PEX-AL-PEX pipe is oxygen barrier, while PPR pipe is non-barrier pipe

So, both of pipes have benefits, and it is hard to say which one is better. Normally for underfloor heating systems, PEX-AL-PEX pipe is preferred by our customers, because it is flexible, easy install, less jointing. But for indoor water plumbing systems, especially for high-rise buildings that higher pressure requested, PPR pipe is a ideal choice.

How to inquire to SUNPLAST for a quote of HDPE pipe?

SUNPLAST is ready to provide our best quality PPR pipes and fittings to all customers around the world.

For 24 hours contact details as below:

Email: export@ sunplastpipe.com

sunplastpipe@gmail.com

Tel: 0086-574-87226883/87467583

Mobile/whatsApp/Wechat: 0086-15968493053/18858041865

- View as

Grey PPR Male Tee

Grey PPR Male Tee for Water Plumbing & heating, sized from dn20-110mm in PN25,green/grey/white colors for choice, produced by superior quality that are warranted with 15 years, best competitive wholesale price & prompt delivery can be met. Contact us for more details of PPR Male Tee from SUNPLAST!!!

Read MoreSend InquiryWhite PPR Male Tee

White PPR Male Tee for Water Plumbing & heating, sized from dn20-110mm in PN25,green/grey/white colors for choice, produced by superior quality that are warranted with 15 years, best competitive wholesale price & prompt delivery can be met. Contact us for more details of PPR Male Tee from SUNPLAST!!!

Read MoreSend InquiryGreen PPR Male Tee

Green PPR Male Tee for Water Plumbing & heating, sized from dn20-110mm in PN25,green/grey/white colors for choice, produced by superior quality that are warranted with 15 years, best competitive wholesale price & prompt delivery can be met. Contact us for more details of PPR Male Tee from SUNPLAST!!!

Read MoreSend InquiryPPR Male Tee

DIN8077/8078 Standard PPR Male Tee for Water Plumbing & heating, sized from dn20-110mm in PN25,green/grey/white colors for choice, produced by superior quality that are warranted with 15 years, best competitive wholesale price & prompt delivery can be met. Contact us for more details of PPR Male Tee from SUNPLAST!!!

Read MoreSend InquiryDIN8078 PPR Male Tee

DIN8078 PPR Male Tee for Water Plumbing & heating, sized from dn20-110mm in PN25,green/grey/white colors for choice, produced by superior quality that are warranted with 15 years, best competitive wholesale price & prompt delivery can be met. Contact us for more details of PPR Male Tee from SUNPLAST!!!

Read MoreSend InquiryPPR Female Elbow For Water Plumbing

PPR Female Elbow For Water Plumbing for Water Plumbing & heating, sized from dn20-110mm in PN25,green/grey/white colors for choice, produced by superior quality that are warranted with 15 years, best competitive wholesale price & prompt delivery can be met. Contact us for more details of PPR Female Elbow/Bend from SUNPLAST!!!

Read MoreSend Inquiry