- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

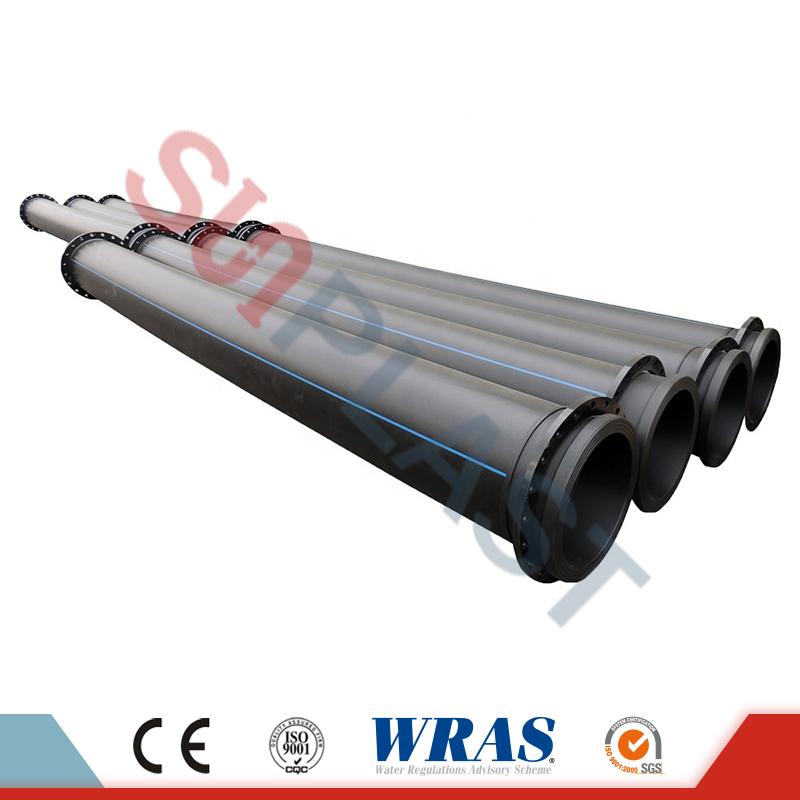

HDPE Dredge Pipe Manufacturers

HDPE pipe has been more & more preferred & used by our customers for dredge works. The HDPE dredge pipes are assembled with flanges at the both ends. By using steel bolts/nuts to fix the the whole HDPE dredge pipe, it can be easily assembled or disassembled.

SUNPLAST HDPE dredging pipe has been a ideal replacement of steel pipe for dredging works, due to superior performance & characteristic that it has:

※ Corrosion resistance: high resistance to attach from various types of chemicals, no electrochemical corrosion, so HDPE dredge pipe can be used for sea water without worry about corrosion problem.

※ High toughness: fracture extension rate of HDPE dredging pipe, commonly more than 500%. As to the uneven settlement of the base, its adaptive ability is very strong, good aseismic performance.

※ Light weight: by comparing steel pipe, the HDPE dredge pipe is only 1/5 of steel pipe on the weight, less pipe floats be needed

※ Easy to assemble or dis-mountable: The HDPE dredge pipe welded with flanges can be assembled or disconnected very easily.

※ Excellent flexible and resistance to scratches ability: HDPE dredging pipe is more flexible than steel pipe, so less rubber hoses be required.

※ Good wear resistance, low wall friction coefficient, small flow resistance, excellent conveying ability: HDPE dredging pipe has a good toughness, smooth wall allows the pipeline has good wear resistance & high flow rate.

※ Low system cost, less maintenance costs, can dramatically reduce the cost for the project: HDPE dredge pipe is much lower price than steel pipe, at the same time more durable use when it is used for sea water.

※ Long service life: HDPE dredging pipe can service longer lifetime in sea water.

※ Recyclable and environment-friendly: HDPE material can be reused, complete with the concept of efficient environmental protection which our state advocates

SUNPLAST HDPE dredge pipe can be supplied from dn110mm to 1200mm, with various SDR ranges. The customers can always find the right pipe for their dredge work.

The steel flanges, which are assembled at both ends, can be drilled into EN1092 standard, or customized-made.

|

SDR Ratings |

SDR33 |

SDR26 |

SDR21 |

SDR17 |

SDR13.6 |

SDR11 |

SDR9 |

|

Normal Pressure (Mpa) |

0.5 |

0.6 |

0.8 |

1.0 |

12.5 |

16 |

20 |

|

Norminal Diameter dn (mm) |

Wall Thickness e (mm) |

||||||

|

110 |

|

4.2 |

5.3 |

6.6 |

8.1 |

10.0 |

12.3 |

|

125 |

|

4.8 |

6.0 |

7.4 |

9.2 |

11.4 |

14.0 |

|

140 |

|

5.4 |

6.7 |

8.3 |

10.3 |

12.7 |

15.7 |

|

160 |

|

6.2 |

7.7 |

9.5 |

11.8 |

14.6 |

17.9 |

|

180 |

|

6.9 |

8.6 |

10.7 |

13.3 |

16.4 |

20.1 |

|

200 |

|

7.7 |

9.6 |

11.9 |

14.7 |

18.2 |

22.4 |

|

225 |

|

8.6 |

10.8 |

13.4 |

16.6 |

20.5 |

25.2 |

|

250 |

|

9.6 |

11.9 |

14.8 |

18.4 |

22.7 |

27.9 |

|

280 |

|

10.7 |

13.4 |

16.6 |

20.6 |

25.4 |

31.3 |

|

315 |

9.7 |

12.1 |

15.0 |

18.7 |

23.2 |

28.6 |

35.2 |

|

355 |

10.9 |

13.6 |

16.9 |

21.1 |

26.1 |

32.2 |

39.7 |

|

400 |

12.3 |

15.3 |

19.1 |

23.7 |

29.4 |

36.3 |

44.7 |

|

450 |

13.8 |

17.2 |

21.5 |

26.7 |

33.1 |

40.9 |

50.3 |

|

500 |

15.3 |

19.1 |

23.9 |

29.7 |

36.8 |

45.4 |

55.8 |

|

560 |

17.2 |

21.4 |

26.7 |

33.2 |

41.2 |

50.8 |

62.5 |

|

630 |

19.3 |

24.1 |

30.0 |

37.4 |

46.3 |

57.2 |

70.3 |

|

710 |

21.8 |

27.2 |

33.9 |

42.1 |

52.2 |

64.5 |

79.3 |

|

800 |

24.5 |

30.6 |

38.1 |

47.4 |

58.8 |

72.6 |

89.3 |

|

900 |

27.6 |

34.4 |

42.9 |

53.3 |

66.2 |

81.7 |

|

|

1000 |

30.6 |

38.2 |

47.7 |

59.3 |

72.5 |

90.2 |

|

|

1200 |

36.7 |

45.9 |

57.2 |

67.9 |

88.2 |

|

|

SUNPLAST HDPE dredging pipe is regularly provided in 5.8m or 11.8m length, which is suitable for container loading. Other length also available as per customer needs.

When HDPE dredge pipe is used for dredge work, it normally assembled together with dredge pipe floats & suction/discharging rubber hoses. The pipe floats provide sufficient buoyancy to support the whole dredging pipeline above the water, while rubber hoses can reduce wobble caused by sea wave.

SUNPLAST is a integrated provider of HDPE dredging pipe, dredge pipe floats & rubber hoses.

Dredge pipe floats are designed & manufactured in barrel shape that can absorb or reduce the energy from vessel collision of sea wave impacting. The dredge pipe floats consists two-halves, each halves can be placed on the HDPE dredge pipe, fixed by steel bolts & nust or bandages.

The dredge pipe floats are by rotational molding technology. One-time rotational molding made outer shell is made of LDPE or MDPE with high wear resistance & inside filled with high strength polyurethane closed-cell foam, which is free of water absorption.

SUNPLAST can provide various dimensions of dredge pipe floats for options, based on the size of HDPE dredge pipe that be used:

Floater I.D.

(HDPE Dredge Pipe O.D.)

Floater O.D.

(mm)

Floater Length

(mm)

Thickness Of MDPE Shell

(mm)

Net Buoyancy

(kg/pcs)

160/180

500

800

6

300

200/225

600

700

7

250

250/280/315

700

900

7

410

315

1100

1000

7

500

355

1100

1100

7

550

400/450

1200

1200

8

1200

450/500

1300

1300

8

1250

500/560

1300

1500

9

1350

560/630

1400

1600

9

1600

630

1480

1600

11

1950

630/710

1550

1800

12

2200

710

1620

1900

12

2300

710/800

1700

2000

13

2700

800

1850

2100

14

3200

900

2000

2400

15

4600

1000

2040

2500

16

4900

1200

2400

2600

16

6500

(mm)

Download Catalogue Of HDPE DREDGE PIPE-PIPE FLOATS-RUBBER HOSES

SUNPLAST is ready to provide our best quality HDPE dredge pipe to all customers around the world.

For 24 hours contact details as below:

Email: export@ sunplastpipe.com

sunplastpipe@gmail.com

Tel: 0086-574-87226883/87467583

Mobile/whatsApp/Wechat: 0086-15968493053/18858041865

- View as

HDPE Dredge Pipe

ISO4427 standard HDPE dredge pipe, available from dn110-1200mm in SDR11/SDR13.6/SDR17/SDR21/SDR26, 5.8 or 11.8m length. Customer-made steel backing rings, high quality with durable service time, best factory prices. Contact us for more details.

Read MoreSend InquiryHDPE Pipe With Flanges For Dredge and Mining

ISO4427 standard HDPE Pipe With Flanges For Dredge and Mining pipe,welded with flanges at the both end, available in 5.8m or 11.8m length,customrized steel backing rings available,high quality at best wholesale price. Contact us for more details of our HDPE dredge pipe!!!

Read MoreSend Inquiry