- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

HDPE Pipe Manufacturers

What’s HDPE pipe?

HDPE pipe, also called high density polyethylene or polyethylene pipe, is made of HDPE granule material. Firstly, it was made by PE63 material, and then PE80 material. Till now, most of HDPE pipe is produced by a improved generation, called PE100 material.

Here in Sunplast, we provide HDPE pipes that are made by PE100 material & PE80 material only.

What’s the meaning of PE63, PE80 & PE100? What’s the difference between the HDPE pipes that are made of PE63, PE80 & PE100?

The designations PE63, PE80 & PE100 are based on the long-term strength of the respective materials, known as the minimum required strength (MRS) in accordance with ISO 12162.

The designations are:

|

Material Designation |

Minimum Required Strength (MRS)MPa |

|

PE63 |

6.3 |

|

PE80 |

8.0 |

|

PE100 |

10 |

The main differences between the HDPE pipe that are made PE63, PE80 & PE100 are the density, viscous stress and quasi-static stress. The HDPE pipe made by PE100 material has a higher strain hardening modulus than PE80 & PE63, and offers better viscous stress and quasi-static stress, which allows thinner pipe wall for the same pressure rating.

For example: for the same diameter HDPE pipe & same wall thick, such as:DN110×10.00mm in SDR11, for PE100 material its pressure rating is PN16 bars, while PN12.5 bars for PE80 & PN10 for PE63.

What’s SDR & PN means in HDPE pipes?

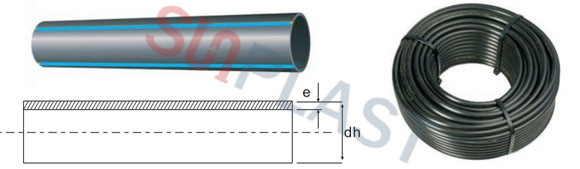

SDR, also called Standard Dimension Ratio, refers to he ratio of the outer diameter to the thickness of the HDPE pipe, which is SDR=OD/WT.

PN refers to nominal pressure of HDPE pipe, referring to the normal pressure for water transportation at 20℃.

For the HDPE pipe made by PE80 & PE100, at the same SDR rating, the PN is different:

Material/SDR

SDR9

SDR11

SDR13.6

SDR17

SDR21

SDR26

PE80

PN16 bars

PN12.5 bars

PN10 bars

PN8 bars

PN6 bars

PN5 bars

PE100

PN20 bars

PN16 bars

PN12.5 bars

PN10 bars

PN8 bars

PN6 bars

What diameters of HDPE pipe can Sunplast provide? And what’s the applicants of Sunplast HDPE pipe?

As a premier manufacturer in China, SUNPLAST can provide HDPE pipe from the diameter dn20-1200mm with various SDR ratings in SDR9-SDR33.

The full specifications of SUNPLAST HDPE pipe as below:

|

SDR Ratings (Standard Dimension Rate) |

SDR33 |

SDR26 |

SDR21 |

SDR17 |

SDR13.6 |

SDR11 |

SDR9 |

|

Normal Pressure (PN) For PE80 (Mpa) |

0.4 |

0.5 |

0.6 |

0.8 |

10 |

12.5 |

16 |

|

Normal Pressure (PN) For PE100 (Mpa) |

0.5 |

0.6 |

0.8 |

1.0 |

12.5 |

16 |

20 |

|

Norminal Diameter dn (mm) |

Wall Thickness e (mm) |

||||||

|

20 |

|

|

|

|

|

2.0 |

2.3 |

|

25 |

|

|

|

|

2.0 |

2.3 |

3.0 |

|

32 |

|

|

|

2.0 |

2.4 |

3.0 |

3.6 |

|

40 |

|

|

2.0 |

2.4 |

3.0 |

3.7 |

4.5 |

|

50 |

|

2.0 |

2.4 |

3.0 |

3.7 |

4.6 |

5.6 |

|

63 |

|

2.5 |

3.0 |

3.8 |

4.7 |

5.8 |

7.1 |

|

75 |

|

2.9 |

3.6 |

4.5 |

5.6 |

6.8 |

8.4 |

|

90 |

|

3.5 |

4.3 |

5.4 |

6.7 |

8.2 |

10.1 |

|

110 |

|

4.2 |

5.3 |

6.6 |

8.1 |

10.0 |

12.3 |

|

125 |

|

4.8 |

6.0 |

7.4 |

9.2 |

11.4 |

14.0 |

|

140 |

|

5.4 |

6.7 |

8.3 |

10.3 |

12.7 |

15.7 |

|

160 |

|

6.2 |

7.7 |

9.5 |

11.8 |

14.6 |

17.9 |

|

180 |

|

6.9 |

8.6 |

10.7 |

13.3 |

16.4 |

20.1 |

|

200 |

|

7.7 |

9.6 |

11.9 |

14.7 |

18.2 |

22.4 |

|

225 |

|

8.6 |

10.8 |

13.4 |

16.6 |

20.5 |

25.2 |

|

250 |

|

9.6 |

11.9 |

14.8 |

18.4 |

22.7 |

27.9 |

|

280 |

|

10.7 |

13.4 |

16.6 |

20.6 |

25.4 |

31.3 |

|

315 |

9.7 |

12.1 |

15.0 |

18.7 |

23.2 |

28.6 |

35.2 |

|

355 |

10.9 |

13.6 |

16.9 |

21.1 |

26.1 |

32.2 |

39.7 |

|

400 |

12.3 |

15.3 |

19.1 |

23.7 |

29.4 |

36.3 |

44.7 |

|

450 |

13.8 |

17.2 |

21.5 |

26.7 |

33.1 |

40.9 |

50.3 |

|

500 |

15.3 |

19.1 |

23.9 |

29.7 |

36.8 |

45.4 |

55.8 |

|

560 |

17.2 |

21.4 |

26.7 |

33.2 |

41.2 |

50.8 |

62.5 |

|

630 |

19.3 |

24.1 |

30.0 |

37.4 |

46.3 |

57.2 |

70.3 |

|

710 |

21.8 |

27.2 |

33.9 |

42.1 |

52.2 |

64.5 |

79.3 |

|

800 |

24.5 |

30.6 |

38.1 |

47.4 |

58.8 |

72.6 |

89.3 |

|

900 |

27.6 |

34.4 |

42.9 |

53.3 |

66.2 |

81.7 |

|

|

1000 |

30.6 |

38.2 |

47.7 |

59.3 |

72.5 |

90.2 |

|

|

1200 |

36.7 |

45.9 |

57.2 |

67.9 |

88.2 |

|

|

Download our price list SUNPLAST HDPE PIPE

Now, SUNPLAST HDPE pipe has been widely used in various fields,such as water plumbing & sewerage system, gas distribution, slurry transfer lines, rural irrigation, fire system supply lines, electrical and communications conduit.,etc, but mainly:

HDPE pipe be used for water is the most popular. HDPE pipe is a green material that can deliver drinkable water, it has been widely used for municipal water supply/drainage systems, fire work systems, sea water desalination works..etc.

HDPE pipe is also widely used for outdoor gas distribution for municipal works.

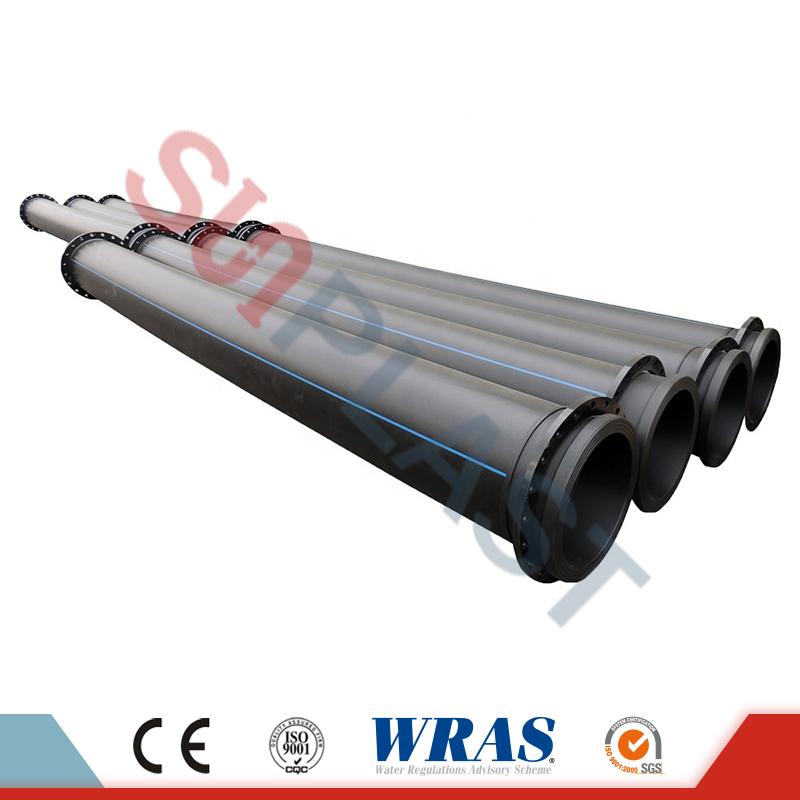

HDPE dredge pipe, which is light weight,abrasion performance & smooth surface, has been a ideal replacement of steel pipe. Assembled with flanges at both ends, HDPE dredge pipe is easy for dredge work at the site

※ HDPE irrigation pipe

HDPE pipe has been more & more popular used for irrigation systems for agriculture. The flexibility allows HDPE irrigation pipe can be coiled in 100/200m length, by using PP compression fittings, it greatly save the installation costs & times. Moreover, due to superior UV resistance performance, HDPE pipe has becomed the most eco. & ideal choice for irrigation systems.

What colors available for HDPE pipe?

SUNPLAST HDPE pipe for drinking water is regular in black colors with blue strips or blue colors.

The HDPE pipe for outdoor gas distribution is in yellow color or black color with yellow strips.

The HDPE pipe for the other usages can be determined between buyer & supplier, but recommend in black color.

What’s the super advantages of HDPE pipe by comparison of the other traditional piping?

The HDPE pipe has become a primary choice of replacement of galvanized steel pipe or other plastic pipe (like PVC pipe) that are used for water, because it reputes many incomparable advantages:

※ Non-Toxic: HDPE pipe made by PE100 or PE80 material only, no heavy metal additives, pollution free, suitable for drinkable water supply.

※ Corrosion Resistance: HDPE is a kind of insert material, which made HDPE pipe to be free affected by acid, alkali and salt. Thanks to corrosion resistance, HDPE pipe can also be serviced for the delivery of salty seawater.

※ High flow capacity: HDPE pipe’s smooth interior walls and low abrasion resistance result low flow resistance and high flow capacity.

※ Excellent Flexibility: Small diameter DN20-63mm HDPE pipe can be supplied in coils, from which fewer fittings be needed, and lower installation costs.

※ Excellent UV resistance: While production of HDPE pipe, a 2%~2.5% of carbon black will be added, this makes HDPE pipe (black color) can be exposed under the sunshine for long time working.

※ Easy & reliable installation: Due to light weight, HDPE pipe is easy to transport & handle friendly.

The HDPE pipe uses hot-melt fusion technology by using a special welding machine. The jointing is much stronger than HDPE pipe itself.

※ Long service time: HDPE pipe can be working for more than 50 years under proper use.

※ Use trenchless installation: The HDPE pipe can be installed by trenchless technology, which will greatly save the installation costs & time.

※ Various fittings available: There various HDPE pipe fittings for options: HDPE socket fusion fittings, HDPE butt fusion fittings, HDPE electrofusion fittings & PP compression fittings.

How to connect HDPE pipes & HDPE pipe fittings?

Luckily, HDPE is a kind of thermal-melt material, and the HDPE pipe & HDPE pipe fittings can be welded by hot-melt technology, which is the most reliable welding method. Once the hot-melt welding is finished, as long as it passes the Hydrostatic pressure test, the whole piping systems will be 100% a leak-free.

Sunplast HDPE pipes & HDPE pipe fittings are mainly connected by 3 hot-melt welding methods:

※ HDPE pipe socket fusion technology

The socket fusion is used to join the HDPE pipe & HDPE pipe fitting from DN20 to DN110 mm of diameter. It is performed by heating the external surface of the hdpe pipe and the internal surface of the HDPE pipe fitting up to achieving the fusion of the material, and then it is inserted one in another while the material is still hot.

※ HDPE pipe butt fusion technology

The Butt Fusion is the most important and widely used method of connection for HDPE pipes larger than 110 mm. It is a method of jointing pipe ends by way of heating and cooling under pressure, resulting in pipe joints as strong as the pipe itself.

The HDPE butt fusion requests the HDPE pipes & fittings have the same outer diameter, and the tolerance of wall thickness of both shall be no exceed 10%, in order to assure the best welding results.

※ HDPE pipe electrofusion technology

The Electrofusion is a simple method of joining HDPE pipes & HDPE pipe fittings in circumstances where butt fusion is not practicable, such as where valves, elbows, and tees must be added.

The HDPE electrofusion fittings have small copper wires coiled around the inside surface of both ends. By using HDPE electrofusion machine, the electric current is then run through those wires in turn melting the HDPE on the inside of the HDPE electrofusion fitting and the outside of the HDPE pipe.

The other regular connection method for HDPE pipe is by mechanical connection: the both connected pipe (or fittings) ends be welded with HDPE flange adaptors, using steel bolts/nuts to fix both ends together. The HDPE pipes & fittings be connected by mechanical connection can be assembled or disassembled easily, which is normally for dredge work or mining works.

PP Compression fittings are also very regular used for small HDPE pipes with diameter dn20-110mm, which is another mechanical connection. The HDPE pipes connected by PP compression fittings are normally for irrigation systems.

What kind of HDPE pipe fittings & HDPE pipe welding machine that SUNPLAST can provide?

SUNPLAST can offer a integrated solution for HDPE piping systems. To support the connection of HDPE pipe, we can also offer full ranges of HDPE pipe fittings & HDPE pipe welding machines. The customers can always find a perfect solution from us based on their design & budget.

SUNPLAST HDPE pipe fittings can be divided into three varieties, which are: PP compression fittings, HDPE butt fusion fittings & HDPE electrofusion fittings

The PP compression fittings are regularly used for the HDPE pipes with small diameters up to DN110mm. No welding & easy installation has made PP compression fittings to be the first choice for small diameter pipe connection.

SUNPLAST can provide PP compression fittings from dn20mm to dn110mm, with working temperature PN16 bars.

Download our price list for SUNPLAST PP COMPRESSION FITTINGS

The HDPE butt fusion fittings are the most common used fittings for HDPE pipe.

SUNPLAST HDPE butt fusion fittings can be produced in wide diameters dn50-dn1200mm, the diameter dn50-800mm are injection moulded while dn900-1200mm is fabricated type.

The HDPE butt fusion fittings are regular in SDR17-PN10 bars & SDR11-PN16 bars. The fabricated type fittings can be provided at any SDR rating based on pipe.

Download our price list for SUNPLAST HDPE BUTT FUSION FITTINGS

HDPE electrofusion fittings provide a more reliable connection for HDPE pipe, which are more & more adopted by our customers.

SUNPLAST HDPE electrofusion fittings can be offered from dn20mm to dn630mm, with pressure rating SDR11-PN16 bars for water.

Download price list of SUNPLAST HDPE ELECTROFUSION FITTINGS

The HDPE pipe welding machine that Sunplast can provide:

HDPE pipe socket fusion machine

The HDPE pipe socket fusion machine is used for the welding of HDPE pipe & HDPE pipe socket fusion fittings with diameter of dn20-110mm.

The HDPE pipe butt fusion machine can be provided in various models, which can be divided into: manual type & hydraulic type.

Manual type is regular for small diameter pipe d50-dn160mm, dn50-dn200mm & dn90-250mm, which is a option of light-weight & cheaper prices.

Hydraulic type: hydraulic type welding machine uses hydraulic pressure to control the HDPE pipe’s movements while welding, providing a certain & stable pressure while welding, which can max. ensure the welding results.

The hydraulic type HDPE pipe butt fusion machine can be produced for all diameters up to 50mm, which are: 63-160mm, 63-200mm, 90-250mm, 160-315mm, 160-355mm, 280-450mm, 280-500mm, 450-630mm, 630-800mm, 710-1000mm, 800-1200mm.

Download the price list of SUNPLAST HDPE PIPE BUTT FUSION MACHINE

HDPE pipe electrofusion machine.

SUNPLAST HDPE pipe electrofusion machine is newly designed for the connection of our HDPE electrofusion fittings.

The HDPE pipe electrofusion welding machines can be offered in four models: SPE315 model is available to weld the diameter dn20-315mm, SPE400 model for the diameter dn20-400mm, SPE500 model for the diameter dn20-500mm while SPE630 model is for dn20-630mm.

Download the price list of HDPE PIPE ELECTROFUSION MACHINE

How do you connect HDPE pipes to the other pipe, such as PVC pipe, steel pipe?

When HDPE pipe be connected to the PVC pipe or steel pipe, since they are not made by HDPE material, so hot-melt welding is not available for connection.

The only possible method to connect HDPE pipe to PVC pipe is by mechanical connection, using flanges or use transition fittings,like female or male thread adaptor fittings.

Which brand of HDPE granule materials that SUNPLAST adopts for the HDPE pipes & fittings?

Material of excel performance is one of the qualification with produce the topping piping system. SUNPLAST adapts the BEST quality PE100/PE80 material from worldwide famous factories only, such as Borealis, Sinopec, Sabic..etc, which are approved by PE100+ association (see: www.pe100plus.com).

Together with the delivery of the material, a certificate of analysis from material suppliers will be requested,which assure the material is qualified.

At the same time, SUNPLAST laboratory shall sampling tests each batch of raw material arrived to the workshop.When the material is approved, the laboratory will issue a qualification certificate. Only the material with qualification certificate (tested & issued by our laboratory) & certificate of analysis (issued by suppliers), it can

be allowed to be used for the production of HDPE pipe & HDPE pipe fittings.

Which standards do SUNPLAST HDPE pipes & fittings be made into?

SUNPLAST HDPE pipes & fittings are made into ISO4427 standard, at the same time, they can also conform to EN12201 standard & AS/NZS 4129/4130 standard, as well as the other international standards.

What certificates can SUNPLAST provide for HDPE pipes?

SUNPLAST HDPE pipe is approved by ISO4427 certificate & CE certificate.

For HDPE pipe fittings, they are approved by CE certificate.

What’s the technical characteristics of SUNPLAST HDPE pipe?

SUNPLAST HDPE pipe, which conforms to ISO4427 standard, can fully meet to all requirements:

Characteristic

Requirements

Test Methods

Physical characteristics for HDPE pipe

Elongation at break of HDPE pipe

≥350 %

ISO 6259

Longitudinal reversion of HDPE pipe

(100±2℃)

≤3%

ISO 2505

Oxidation induction time of HDPE pipe

(200℃)

≥20min.

ISO 11357-6:2002

Melt Flow Rate of HDPE pipe

(5Kg,190℃,10min.)

Change of MFR by

processing±20%

ISO 1133:2005

Mechanical characteristics for HDPE pipe

Hydrostatic strength of HDPE pipe

at 20℃

For PE80 Pipe

20℃, 100h, 10Mpa

No leak, No break

ISO 1167

For PE100 Pipe

20℃, 100h, 12.4Mpa

No leak, No break

Hydrostatic strength of HDPE pipe

at 80℃

For PE80 Pipe

80℃, 165h, 4.5Mpa

No leak, No break

ISO 1167

For PE100 Pipe

80℃, 165h, 5.4Mpa

No leak, No break

What’s the packing methods of SUNPLAST HDPE pipe?

SUNPLAST HDPE pipe is flexible. For the HDPE pipe with small diameter dn20-63mm, it can be packed in coils with 50m/100m/200m length.

The HDPE pipe with diameter dn75-1200mm, it will be packed in bars with 5.8m length or 11.8m length (for container shipment). Other lengths are also available as per buyer’s requests.

The HDPE pipe shall be horizontally stacked, the stacking height shall be less than 1.5m. To protect the pipe, a covering shall be used when it is stacked outside.

How to inquire to SUNPLAST for a quote of HDPE pipe?

SUNPLAST is ready to provide our best quality HDPE pipes to all customers around the world.

For 24 hours contact details as below:

Email: export@ sunplastpipe.com

Tel: 0086-574-87226883/87467583

Mobile/whatsApp/Wechat: 0086-15968493053/18858041865

- View as

Blue HDPE Pipe For Water Supply

ISO4427/4130/BS EN 12201 standard Blue HDPE Pipe For Water Supply,produced from dn20-1200mm with pressure rating of PN5-PN20 bars,high quality warranted with 15 years,approved by CE certificate & BS6920 test report, complete HDPE pipe fittings available. Contact us for more details of HDPE water supply pipe from SUNPLAST!!

Read MoreSend InquiryBlack HDPE Pipe For Water Supply

ISO4427/4130/BS EN 12201 standard Black HDPE Pipe For Water Supply,produced from dn20-1200mm with pressure rating of PN5-PN20 bars,high quality warranted with 15 years,approved by CE certificate & BS6920 test report, complete HDPE pipe fittings available. Contact us for more details of HDPE water supply pipe from SUNPLAST!!

Read MoreSend InquiryBlue HDPE Pipe

ISO4427/4130/BS EN 12201 standard Blue HDPE Pipe,produced from dn20-1200mm with pressure rating of PN5-PN20 bars,high quality warranted with 15 years,approved by CE certificate & BS6920 test report, complete HDPE pipe fittings available. Contact us for more details of HDPE water supply pipe from SUNPLAST!!

Read MoreSend InquiryBlack Poly Pipe

ISO4427/4130/BS EN 12201 standard Black Poly Pipe,produced from dn20-1200mm with pressure rating of PN5-PN20 bars,high quality warranted with 15 years,approved by CE certificate & BS6920 test report, complete HDPE pipe fittings available. Contact us for more details of HDPE water supply pipe from SUNPLAST!!

Read MoreSend InquiryBlack HDPE Pipe

ISO4427/4130/BS EN 12201 standard Black HDPE Pipe,produced from dn20-1200mm with pressure rating of PN5-PN20 bars,high quality warranted with 15 years,approved by CE certificate & BS6920 test report, complete HDPE pipe fittings available. Contact us for more details of HDPE water supply pipe from SUNPLAST!!

Read MoreSend InquiryPoly Pipe For Water Supply

ISO4427/4130/BS EN 12201 standard Poly Pipe For Water Supply,produced from dn20-1200mm with pressure rating of PN5-PN20 bars,high quality warranted with 15 years,approved by CE certificate & BS6920 test report, complete HDPE pipe fittings available. Contact us for more details of HDPE water supply pipe from SUNPLAST!!

Read MoreSend Inquiry